Friction Shims

Coatings

ATELA SA

À PROPOS DE NOUS

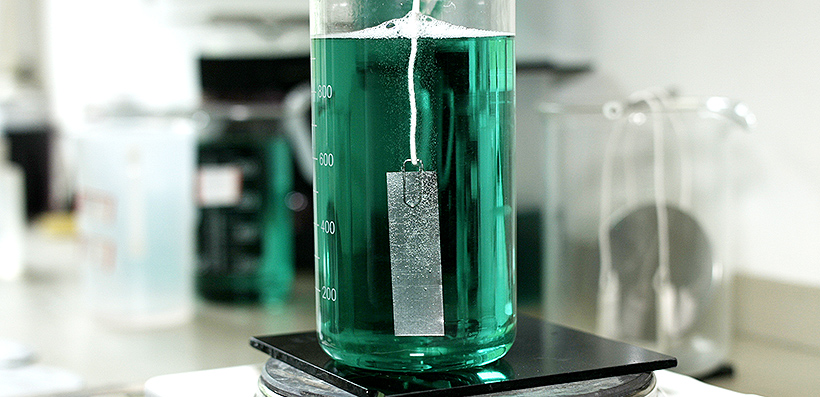

En tant que pionnier du nickel-chimique nous avons acquis et développé notre savoir-faire jusqu’à devenir le leader dans le domaine des revêtements fonctionnels.

Nous avons ainsi développés des revêtements composite, apportant des améliorations techniques et tribologiques importantes. Nos traitements ont des propriétés fonctionnelles telle qu’une protection accrue contre l’usure, une augmentation ou une réduction du coefficient de frottement, et une protection contre la corrosion.

NOS COMPETENCES

Depuis notre fondation en 1959, nous avons su gagner la confiance de nos partenaires en leurs offrant des services et un conseil personnalisé. Après plus de six décénies d’histoire nous continuons notre développement avec l’agrandissment et la digitalisation de la société, la mise en place d’un système de management de la qualité, l’obtention des certification ISO9001 et ISO14001

Nos solutions sont utilisées dans de multiples domaines en répondant aux besoins et aux exigences spécifiques d’industries tel que l’horlogerie, l’aérospatial, la machine outil, la course automobile, l’injection plastique et l’énergie.